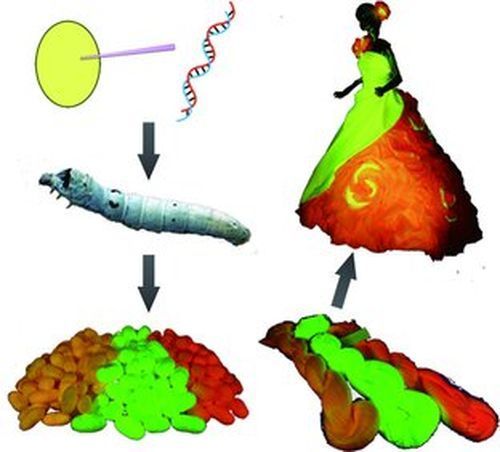

GM silkworms bred to spin red, green and orange fluorescent silk

See on Scoop.it – Virology and Bioinformatics from Virology.ca

Scientists in Japan have genetically engineered silkworms to create red, green or orange silks that glow under fluorescent lights.

The silkworm is the larval form of the domesticated silkmoth (Bombyx mori) and is one of only two insects domesticated by humans (the other being the bee). The larvae build a cocoon around themselves in which to pupate, and each cocoon is made from a fine protein thread of silk up to 900 meters in length. Silk is made by harvesting the cocoons (with larvae inside) and softening them so the threads can be reeled. Around 6,000 cocoons are needed to make a kilogram of silk. Normal silk is a soft, white thread.

Now a research team led by Tetsuya Iizuka and Toshiki Tamura of the National Institute of Agrobiological Sciences in Ibaraki, Japan, has genetically modified the silkworm by transplanting genes from organisms that produce fluorescent proteins into the silkworm genome at the site coding for the silk fiber protein fibroin. The genes they used to make the transgenic silkworms came from the Fungia concinna coral (orange), Discoma coral (red) or jellyfish (green).

Silkworms had previously been genetically modified to produce human collagen proteins and spider silk. Co-author Tamura, said they had earlier produced green fluorescent protein that was used to make beautiful silks, and the new research extended the method to produce the three fluorescent silks in large enough amounts to be useful in making fabrics.

The colored silk made by the over 20,000 transgenic silkworms raised in the lab has been demonstrated to remain vibrant in color under fluorescent light for over two years. In other types of light the colors are less noticeable.

Turning the threads into a fabric presented another challenge for the team because the normal method of producing silk (heating cocoons to 100 degrees C) destroys the fluorescent proteins. Their experiments showed that the cocoons could be softened and reeled by using a weak alkaline solution and heating them to lower temperature in a vacuum. Tamura said this more complex process would mean the fabric would be slightly more expensive than ordinary silk.

See on phys.org